Investing in a new M&J shredder?

Investing in a new shredder involves many considerations and steps. Fortunately, our team of specialists are here to guide you every step of the way.

Our top priority is simple:

Helping you get off to a good start

01. Requirements analysis

We help analyse your waste composition and operational needs to find the best shredder for you.

{more}

No two waste streams are alike. That’s why choosing the right shredder starts with a detailed understanding of your specific waste types, processing goals, and operating conditions.

At M&J Recycling, our experienced Applications Team helps you analyse material composition, density, and output requirements to ensure the best fit.

Whether you’re targeting a specific grain size, high throughput, or improved energy efficiency, we’ll guide you towards the ideal solution. Working closely with our dedicated Sales Team or local partners, we make sure your shredder is built for your operation – delivering performance, reliability, and long-term value from day one.

02. Project management

We help manage every step of the planning process and tailor it to your needs for seamless implementation.

{more}

To ensure smooth implementation of your new shredder, our skilled project management team will help you plan the entire implementation process. Based on a kick-off meeting with all stakeholders, they plan the process and give you a timeline covering shipping, installation, commissioning and other elements your operations require, and ensure all involved parties commit to it.

As part of their services, our project team can help you incorporate the new M&J shredder in your plant layout using STP-files, guide you to the best position of your shredder for optimal flow/operation, provide electrical documentation, coordinate with suppliers of conveyers, power-pack, etc. All to give you a worry-free setup and get your operation up and running smoothly.

03. Installation

We take care of assembly and installation at your facility, making sure everything meets local standards and requirements.

{more}

Our skilled our service technicians will ensure the shredder is assembled and installed in your facility. The M&J team works closely with trained local service partners, who have been certified to handle installation and commissioning of M&J shredders.

This way, you get the benefit of in-depth knowledge of M&J’s solid waste shredders, as well as profound knowledge of the local waste types, installation considerations etc.

04. Operation and safety training

We train you on how to operate M&J shredders safely and efficiently.

{more}

Safety is of utmost importance when you operate equipment as powerful as M&J shredders. So, as part of your shredder’s implementation, we always provide theoretical and practical training that gives all relevant employees the necessary knowledge and skills to operate M&J equipment safely and efficiently.

The training will always take place at your facility, and it results in a safety certification.

05. Commissioning

We make sure your new shredder is commissioned to your specifications and performs to M&J’s high standard.

{more}

Once your waste shredder has been assembled and installed, the commissioning phase begins. Depending on your specifications, this may include hot commissioning and a factory acceptance test. M&J’s experienced service technicians—or our trusted service partners—will be on-site throughout the process to ensure a smooth start-up. Their expertise guarantees that your shredder operates to M&J’s high standards from day one.

06. Proactive maintenance

We help ensure that your shredder keeps performing at the same high level day after day.

{more}

Once your new shredder is operational, focus shifts to keeping your production at the same high level day after day, so you get the most out of your investment. To do this, make sure you schedule in proactive maintenance from M&J authorized service technicians.

M&J’s pre-shredders are designed to wear slowly. They run at slow speeds with high torque, ensuring a high throughput, with reduced wear on the knives, yet even the toughest and most hard-wearing shredders will need new parts at some point.

Scheduling in maintenance will help keep your operations performing optimally and prevent costly breakdowns.

The best results are achieved with a service maintenance agreement, which ensures ongoing proactive maintenance and keeps your shredders in peak performance at all times. Contact us to find out more about service maintenance agreements.

M&J Recycling Training Academy

Already own an M&J shredder?

Intelligent upgrades that deliver results

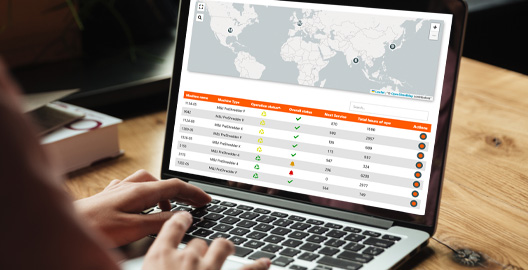

Software upgrades for smarter shredding

An M&J shredder is an investment that evolves over time. Our continuous software upgrades enhance reliability, efficiency, safety, etc. to ensure that your shredder always performs at its best, long after installation.

Upgrade from hydraulic to electric drive

Looking to cut energy costs and reduce maintenance? You can convert your hydraulic pre-shredder into an electric model, giving you all the benefits of eDrive without the upfront cost of a new shredder.