Découvrez des références du monde entier

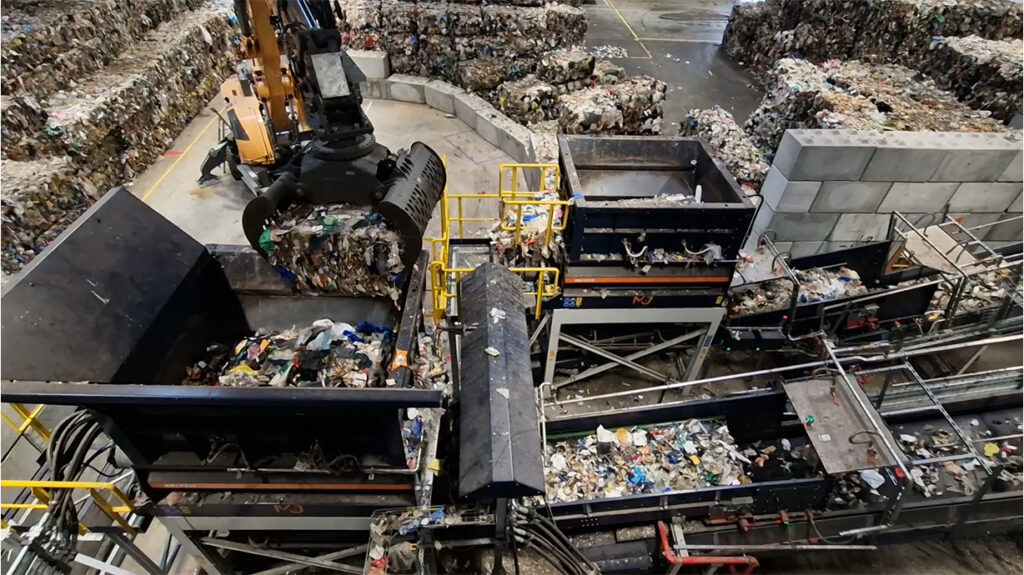

Shredding plastic waste at Resource Denmark

Watch how two M&J K210 pre-shredders process plastic waste at Denmark's largest plastic waste sorting facility, ReSource Denmark.

Rockwood Sustainable Solutions: The M&J shredder outruns our screeners, our belts – and everything else we tested

After Rockwood Sustainable Solutions invested in an M&J 4000M, the company has been able to shred 100 tons extra C&D waste daily.

Read More

Smart Recycling: The M&J 4000M shredder was the missing piece of the puzzle

Investing in an M&J 4000M to pre-shred problematic materials has been a game-changer for Smart Recycling’s operations.

Read More

Ambiente Italia Acerra: “We wanted to work without compromises, so we chose M&J shredders”

Reliable waste shredders and local service make Ambiente Italia Acerra able to process challenging waste types without compromises.

Read More

Terra: We chose the M&J P250e shredder simply because it is electric and can half our energy consumption

Getting an electric pre-shredder has made it possible for Terra to produce RDF with lower operating expenses.

Read More

EHJ Energi: e-drive has made a huge difference in RDF production

Getting an electric fine-shredder has increased productivity and reduced operating costs for EHJ Energi's RDF production.

Read More

Machine mobility and local presence is key

A powerful pre-shredder on crawlers gave SR2 Advisory the freedom to move around their landfill site and remediate legacy waste for RDF production.

Read More

P. Olesen A/S: Our new shredder is cheaper to run and has given us shorter workdays

A larger and more powerful electric shredder has made it possible to get to the bottom of P. Olesen's waste piles.

Read More

Guaranteed output size and proven track record makes the difference for Thailand’s RDF pioneer

Two waste treatment lines with M&J pre-shredders and fine-shredders enable N15 Technology to process 400 tonnes of municipal waste every day.

Read More

Stable production frees up resources for other tasks

Using the powerful and stable M&J 4000S as part of a largely automated waste treatment line has helped Geocycle improve their working environment and free up resources to handle other tasks.

Read More

Exceptional capacity and superb end product

A fully automatic recycling system guarantees Ragn-Sells stable operation and a homogeneous RDF end product for the cement industry.

Read More

Fully automatic RDF production very close to the customer

Two plug-and-play shredders and an automated production line enable Geminor to turn 1,700,000 tonnes of waste into energy for the cement industry every year.

Read More

Les experts M&J

Chaque flux de déchets raconte une histoire différente. Le choix du broyeur dépend entièrement de ce que contient ce flux – une analyse précise se traduira par de meilleures performances, des coûts réduits et des opérations optimisées.

— Dorthe Larsen, Application Manager

Obtenez de l’aide pour trouver le broyeur adapté

Avec de nombreux facteurs à prendre en compte, choisir le bon broyeur n’est pas toujours facile – c’est là que nos experts interviennent, prêts à vous guider.