그리고

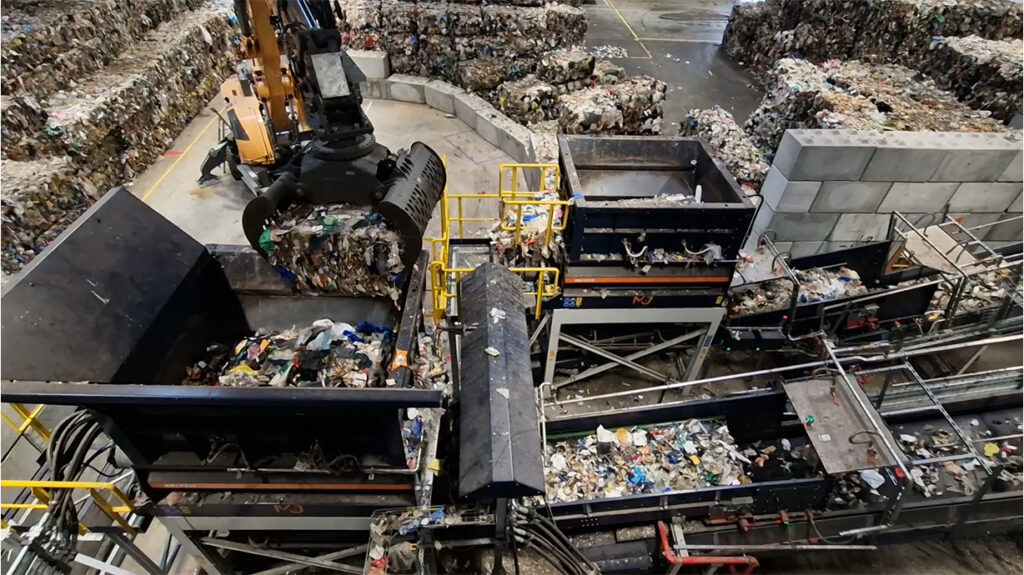

Shredding plastic waste at Resource Denmark

Watch how two M&J K210 pre-shredders process plastic waste at Denmark's largest plastic waste sorting facility, ReSource Denmark.

Rockwood Sustainable Solutions: The M&J shredder outruns our screeners, our belts – and everything else we tested

After Rockwood Sustainable Solutions invested in an M&J 4000M, the company has been able to shred 100 tons extra C&D waste daily.

Read More

Smart Recycling: The M&J 4000M shredder was the missing piece of the puzzle

Investing in an M&J 4000M to pre-shred problematic materials has been a game-changer for Smart Recycling’s operations.

Read More

Ambiente Italia Acerra: “We wanted to work without compromises, so we chose M&J shredders”

Reliable waste shredders and local service make Ambiente Italia Acerra able to process challenging waste types without compromises.

Read More

Terra: We chose the M&J P250e shredder simply because it is electric and can half our energy consumption

Getting an electric pre-shredder has made it possible for Terra to produce RDF with lower operating expenses.

Read More

EHJ Energi: e-drive has made a huge difference in RDF production

Getting an electric fine-shredder has increased productivity and reduced operating costs for EHJ Energi's RDF production.

Read More

Machine mobility and local presence is key

A powerful pre-shredder on crawlers gave SR2 Advisory the freedom to move around their landfill site and remediate legacy waste for RDF production.

Read More

P. Olesen A/S: Our new shredder is cheaper to run and has given us shorter workdays

A larger and more powerful electric shredder has made it possible to get to the bottom of P. Olesen's waste piles.

Read More

Guaranteed output size and proven track record makes the difference for Thailand’s RDF pioneer

Two waste treatment lines with M&J pre-shredders and fine-shredders enable N15 Technology to process 400 tonnes of municipal waste every day.

Read More

Stable production frees up resources for other tasks

Using the powerful and stable M&J 4000S as part of a largely automated waste treatment line has helped Geocycle improve their working environment and free up resources to handle other tasks.

Read More

Exceptional capacity and superb end product

A fully automatic recycling system guarantees Ragn-Sells stable operation and a homogeneous RDF end product for the cement industry.

Read More

Fully automatic RDF production very close to the customer

Two plug-and-play shredders and an automated production line enable Geminor to turn 1,700,000 tonnes of waste into energy for the cement industry every year.

Read More

M&J의 공정 전문가

각각의 폐기물은 저마다 다른 특셩을 가집니다. 올바른 제품의 선정을 위해서는 폐기물에 대한 정확한 이해가 필요합니다. 해당 분석을 올바르게 수행하면 성능 향상, 비용 절감을 통하여 운영 개선에 큰 도움이 됩니다.

— 도르테 라르센, 애플리케이션 매니저

M&J 전문가의 도움을 받아 최적의 제품을 선정하세요.

다양한 요소를 고려하여 올바른 제품을 선정하는 것은 단순한 일이 아닙니다. M&J가 도와드리겠습니다.