Waste-To-Fuel

Energy-efficient fuel without impurities or low-energy substances

Waste presents a stable and profitable energy source. Used and disposed materials can be converted into energy-efficient fuels, which serve as a sustainable alternative to traditional energy sources in various applications.

We know how to optimize alternative fuels

Improve efficiency: By reducing the size of waste, the screening and sorting process becomes more efficient, allowing for better separation of valuable materials.

Increase production volume: Homogeneous, high-quality material ensures a consistent flow during fuel production, resulting in higher output.

Higher calorific value: The removal of impurities and low-energy substances significantly enhances the fuel's energy content, improving combustion performance.

Reliable support: We offer 24/7 expert service and maintenance to ensure smooth operation and continuous fuel production.

Enhance the energy output of alternative fuels

Alternative fuels, such as refuse-derived fuel (RDF) and solid recovered fuel (SRF), are primarily produced from municipal, commercial, and industrial waste. These fuels present significant potential by reducing reliance on fossil fuels and converting waste into usable energy sources.

Through effective pre-shredding, sorting, and impurity removal, alternative fuels can be produced at a higher quality, leading to better combustion and energy output. Optimizing the production process increases the calorific value of waste fuel, making it suitable for a variety of energy applications, from waste-to-energy plants to cement production.

Our industrial shredders and comprehensive support services enable companies worldwide to maximize the value of their alternative fuels, ensuring efficient waste conversion regardless of the material being processed.

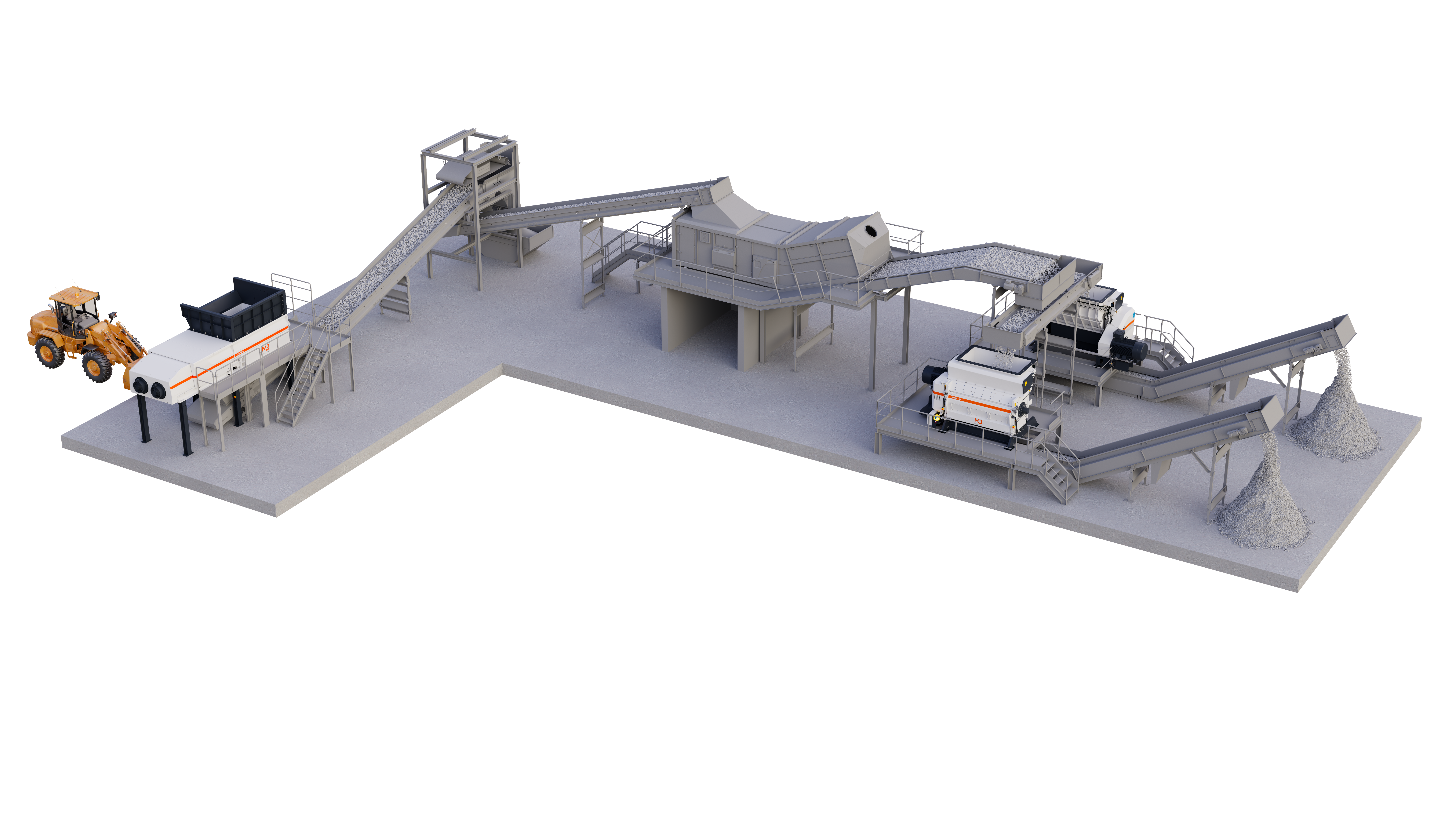

Comprehensive Waste Treatment Solutions

At M&J Recycling, we know that delivering the best results in waste processing goes beyond just offering advanced shredding equipment. It requires a fully integrated system that is reliable, efficient, and tailored to your needs. While our pre-shredders and fine-shredders set the groundwork and complete the job, we collaborate with a broad network of industry partners to deliver a complete, cutting-edge waste treatment line solution.

Unrivaled pre-shredding capabilities

Our pre-shredders, like the M&J P250e series, are engineered to take on the toughest waste streams effortlessly. Built with a patented modular design, they provide:

- Superior Performance: Featuring advanced cutting technology and bi-directional shredding, our pre-shredders ensure consistent torque and powerful processing for all types of waste.

- High Throughput: With capacities of up to 200 tons per hour, our machines ensure a steady flow of shredded material, optimizing the efficiency of downstream sorting processes.

- Simple Maintenance: The modular design allows for quick replacement of worn components, minimizing downtime and keeping operational costs low. With the M&J P250e, maintenance is straightforward, without needing to disconnect hydraulic lines or high-pressure systems.

Excellence in Fine-Shredding

At the final stage of the waste treatment line, our fine-shredders, such as the M&J F240e, produce high-quality Solid Recovered Fuel (SRF):

- Consistent Output: Our advanced cutting systems deliver uniform particle sizes, ideal for SRF production, with minimal fines and oversized pieces.

- Energy Savings: The M&J F240e’s innovative e-drive can cut energy use by up to 35% compared to other solutions, reducing operational costs.

- High Capacity & Robust Design: Capable of processing up to 28 tons per hour, our fine-shredders ensure reliable performance, extending intervals between maintenance and reducing downtime.